Carton Flow Rack Glossary of Terms | Mallard Best Practices

SOLUTIONS

FOR THE TOUGHEST APPLICATIONS

"*" indicates required fields

Sometimes we need to be on more than just the same page… we need to be speaking each other’s language. Well, thankfully the team at Mallard speaks gravity flow and we’ve updated our carton flow rack glossary to help simplify product applications, ordering, installation and maintenance by making sure we are using the same terms. We are eager to assist you with your carton flow project, just give us a call.

Carton Flow Rack Glossary

Bay – area between uprights and individual beam levels. Carton flow rails or tracks are mounted in the bay to form a level or “shelf” of carton flow rack.

Bay Depth – distance from charge/load side of carton flow and front pick face.

Bay Width – distance between upright to upright.

Beam Ties – steel rack supports that are secured to the front and rear beams parallel to the carton flow tracks. They can be retrofit to existing systems to improve system stability and increase capacity while also preventing beam deflection.

Bearing Rollers – Cart-Trak roller tracks are available with bearing rollers offering benefits over standard roller rack such as needing less rollers per track and a lower pitch needed to effectively move the inventory.

Case Flow – carton flow racking system designed for case storage and full or split-case picking.

Case Flow – carton flow racking system designed for case storage and full or split-case picking.

Charge Side – the side of the carton flow rack where inventory is loaded and replenished.

Discharge Side – pick aisle where inventory is extracted from the carton flow rack.

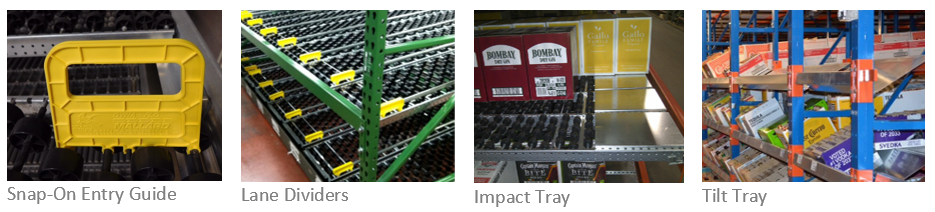

Entry Guides – snap on guides to help workers quickly and accurately identify SKU lanes.

Impact Tray – galvanized steel tray mounted flush on the charge side of the system to take the repeated abuse of heavy carton loading and protect the wheels or rollers. Cartons are loaded then slid onto the wheels or roller tracks.

Lane Dividers – easy to install steel rods separate SKU lanes for the full length of the carton flow track. Beneficial for faster, more accurate loading and picking as well as protecting fragile inventory and meeting regulatory standards where applicable.

Lane Dividers – easy to install steel rods separate SKU lanes for the full length of the carton flow track. Beneficial for faster, more accurate loading and picking as well as protecting fragile inventory and meeting regulatory standards where applicable.

Levels – multiple carton flow levels fit within a single bay, depending on the height of the product, carton or tote being stored. The number of levels can vary from bay to bay, underscoring the efficiency inherent in this type of dynamic storage option.

Dyna-Flo mounting brackets

Mounting Brackets – secure the carton flow track or rail to the front and rear beams. There are customized mounting brackets for our carton flow products depending on use with structural or roll-formed beams. For structural beams, a different mount is required for standard c-channel beams than for reverse beams. And depending on the carton flow product, for roll-formed step beams, there are unique mounting brackets as well. Find the best mounting bracket for your needs in our Mounting Bracket Spec Sheet.

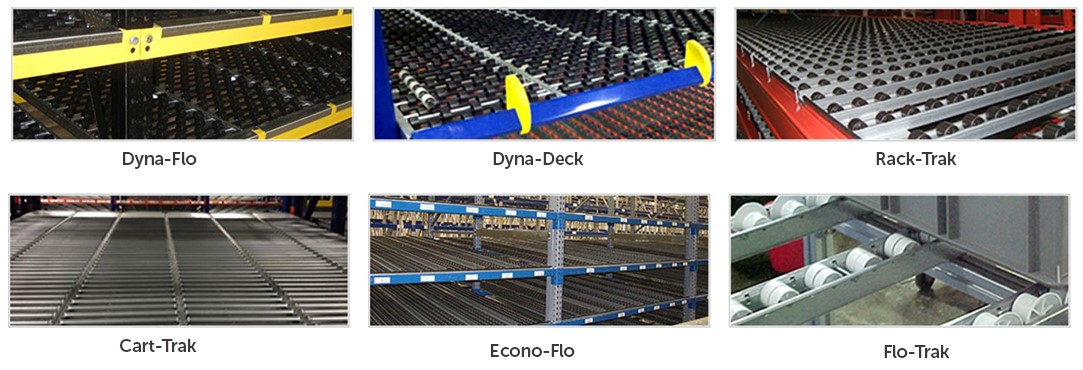

Replacement Carton Flow – Dyna-Deck is specially designed to easily drop-in and replace old, broken or inferior carton flow.

Roller centers – the diameter of the carton flow roller. Cart-Trak carton flow rollers, for example, are available in 1”, 2”, or 3” centers. Why the options? We design the flow rack to meet the demand of the inventory so lightweight or footed-bottomed totes for example may flow best on 1” centers vs heavy beverage cases that may flow better on the larger rollers.

Roller Tracks – often referred to as pencil rollers or roller rack conveyor-style carton flow, is comprised of (no surprise) galvanized rollers providing full carton coverage and superior flow for consistent carton or tote sizes. Mallard offers Cart Trak in 6”, 9” 12” & 16” roller track width.

Track Sizes – Dyna-Deck, Dyna-Flo & Dyna-Flo HD all offer 12″-16″ width tracks. Six 16″ tracks would be used to create a 96″ clear bay, for example. Cart-Trak roller carton flow is available in 6″, 9″, 12″ and 16″ roller widths. Econo-Flo, and Flo-Guide are individual rails of wheeled carton flow; therefore, a set number of rails would make up a carton flow level depending on inventory specs.

Track Sizes – Dyna-Deck, Dyna-Flo & Dyna-Flo HD all offer 12″-16″ width tracks. Six 16″ tracks would be used to create a 96″ clear bay, for example. Cart-Trak roller carton flow is available in 6″, 9″, 12″ and 16″ roller widths. Econo-Flo, and Flo-Guide are individual rails of wheeled carton flow; therefore, a set number of rails would make up a carton flow level depending on inventory specs.

Tilt Tray – attaches to the discharge side of the carton flow bed and serves to improve inventory visibility for faster, more accurate picking. The tilt tray provides more ergonomic picking requiring less bending and reaching by workers.

Totes or Containers – carton flow isn’t just for “cartons”. If you’re using totes to store parts for manufacturing, steel containers for dairy products, cardboard boxes for finishing or to pick from… carton flow rack can be designed to improve your order fulfillment pick rates and accuracy.

Tote Flow – carton flow racking configured to optimize tote storage and pick, pack and ship operations. Be sure to call the Mallard team for flow rack design tips for totes of varying sizes and shapes.

Shelf – track or rollers set adjacent form a carton flow level also called a shelf.

Skid Plates – Skid plates are flat, steel plates that easily drop onto wheeled or roller track and lock into position to slow heavy cartons and control the flow.

SKUs – SKU stands for Stock Keeping Unit and it refers to the alfa-numeric code used to identify individual and distinct products for inventory tracking.

Carton Flow Work Cell Mobile Cart

Slope – the level of pitch that the carton flow track is set on to effectively move the inventory from the rear load side of the system to the opposite discharge or pick side.

Wheeled tracks – Dyna-Flo & Dyna-Flo HD are examples of wheeled track carton flow. It is a durable, full-bed design of staggered polypropylene wheels that allows for consistent wheel coverage no matter what size or shape your inventory takes. Perfect for product mixes with multiple and/or varying SKUs.

Work Cell – Carton flow work cells are wheeled mobile carts equipped with carton flow tracks. The carts are quick to build and can be moved where needed, when needed. Perfect for parts storage, assembly, shift changes, FIFO item picking, and more. Move by hand or with optional tow bar for forklift.

Find the Best Carton Flow Application

Carton flow is designed to optimize the speed and accuracy of inventory storage and selection for cartons, cases, eaches, and tote-stored items. But not all carton flow is created equal. The Mallard team is ready to help you find the best carton flow configuration to meet the unique needs of your operation. We can also test the lane design before finalizing the carton flow order, just give us a call.

Learn more about carton flow applications and design:

Cartons Flow on Carton Flow – Wheeled vs Roller System Design | Mallard Best Practices

Choosing Between Dyna-Flo or Dyna-Flo HD Carton Flow | Mallard Best Practices

7 Mistakes to Avoid When Ordering Carton Flow Rack