Carton Flow Rail Capacity – Ready, Set, Flow | Mallard Best Practices

SOLUTIONS

FOR THE TOUGHEST APPLICATIONS

"*" indicates required fields

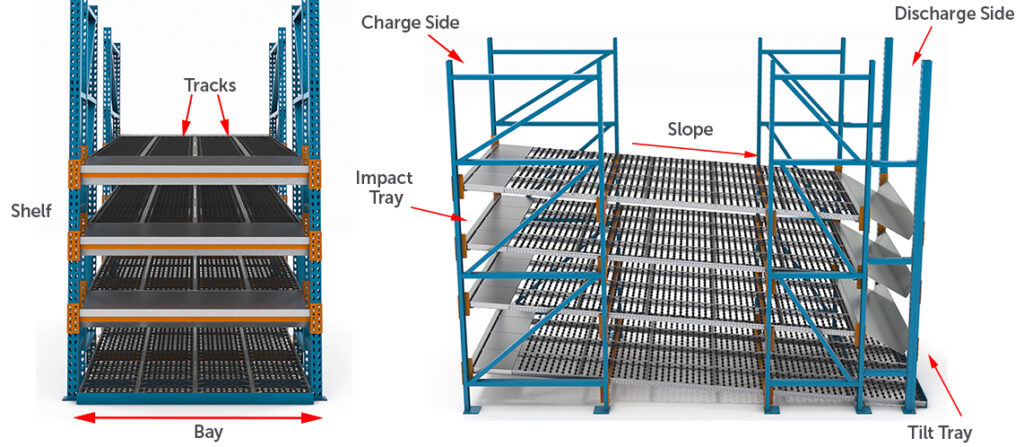

Carton flow rack is a dense storage solution that organizes cartons, totes, and individual pieces of inventory to support fast, accurate item selection. Designing the system to deliver on those expectations requires careful selection of the right components and constructing the lanes to handle the load capacities day-in and day-out.

Mallard offers several options to meet carton flow rail capacity needs and provide practical, long-term, dependable solutions. Using your carton or packaging specs, i.e., dimensions, load weight, bottom surface area, features, and the order picking process, you will be able to meet your inventory goals.

Begin the design process by looking at wheeled vs. roller carton flow to see which configuration will best meet your inventory needs.

Carton Flow Rack Wheels vs. Rollers

Mallard carton flow rails are available in both Dyna-Flo wheeled and Cart-Trak roller rails with varying styles of each to accommodate all inventory and packaging types. There are several reasons for choosing one style over the other.

Inventory Specs:

- Wheeled track is an excellent choice for inventory that varies in size. The full-wheel bed design lets you position the lanes anywhere across the bed to accommodate each SKU in a dedicated lane. The full-wheel bed coverage also allows for easy reprofiling of changing SKUs.

- Roller track is used for consistently sized inventory. The rail width should closely match the package width to provide full coverage for cartons or totes. Tracks may require replacement if inventory specs change significantly.

Roller carton flow rack – Cart-Trak & Cart-Trak HD (heavy-duty) |

Wheeled carton flow rack – Dyna-Flo & Dyna-Flo HD |

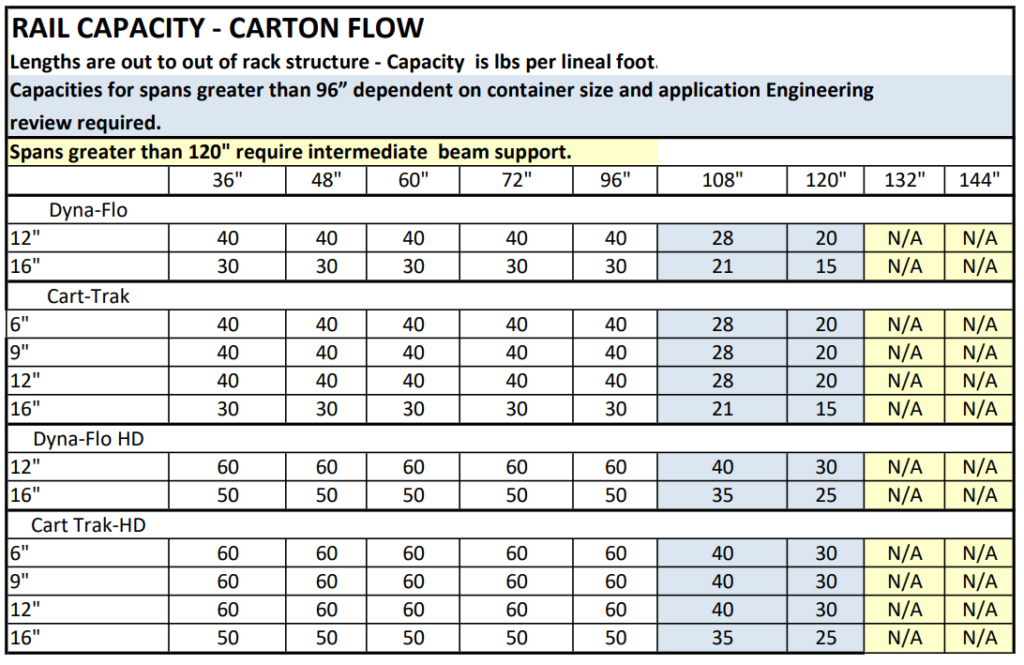

Carton Flow Rail Capacity

Besides the style of carton or packaging, you will want to ensure that your carton flow system will be sturdy enough for long-lasting use. Under anticipating capacity can lead to broken and inferior performance and added expense. As a rule, we refer to this capacity chart as a Guideline for carton flow rack capacity.

Wheeled track

- Wheel density impacts the capacity. The denser the greater capacity.

- Using narrow rails can increase capacity

- Dyna-Flo rails come in 12” & 16” wide sections to fit most standard bay sizes

- Six rails of 16” fit a 96” bay

Roller track

- Roller spacing and type of roller will directly affect the rail capacity

- Cart Trakcomes in 6”, 9” 12” & 16” roller track widths

Preventing Carton Flow Rack Overload

Inventory changes are often the catalyst for system overload. Weight increases can not just cause the carton flow to work less effectively meaning hang-ups, and broken parts, but heavy cartons and cases can cause possible worker injury if the system is under-designed. Most often, overload causes:

- Beam deflection – bending outward and possibly twisting, causing a safety concern for the system.

- Lane shifting – cartons can leave their designated lanes as they flow down, causing hang-ups and possible SKU confusion for workers.

- Improper flow – Too heavy cases may pick up speed in the lane and hit with too much force at the pick aisle or against other inventory, causing damage. Workers are vulnerable to injury as well.

- Rails dislodging – if the carton flow rails are under too much pressure, they can dislodge from the rack system and cause inventory to drop, possibly causing worker injury and inventory damage.

It’s best always to reexamine your carton flow rail capacity if you experience inventory load changes that maximize or overtax your established load capacity. The Mallard team is here to help you find the most effective solution.

Cart-Trak Carton Flow with Tilt Tray

Carton Flow Rack Accessories

Customize your carton flow rack to deliver the most effective results and meet order picking objectives quickly, safely, and accurately.

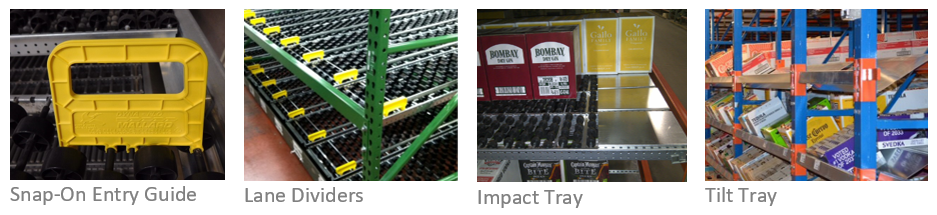

Lane entry guides help designate individual SKU lanes in wheeled carton flow. They simply snap onto the lane at the load side to help your workers quickly and accurately load inventory. Entry guides come in short, tall, and heavy-duty options.

Full-length lane dividers help keep SKUs separate from load to pick aisle. They improve order pick accuracy and ensure compliance with separating SKUs where needed. Mallard offers two styles of full-length lane dividers – snap-on and heavy-duty. Dividers can also provide stability for tall and unstable inventory packaging. They are adjustable on one-inch intervals and designed for fast positioning to quickly accommodate reprofiling.

Tilt tray is a durable steel tray installed at the pick aisle side of the flow rack. It can be angled to achieve optimal pick positioning from any of the carton flow levels.

Impact tray is a durable steel tray installed on the load-side of the carton flow rack to take the brunt force from the repeated loading of heavy cartons. Cartons are loaded onto the impact tray then simply slid onto the flow lane. Impact trays protect the carton flow wheels or rollers from damage.

Simplify Carton Flow Design

Clearly, a lot goes into carton flow rack design and preparing the system for load capacities and inventory that will successfully support your order picking operation today and into the future. If you have questions or want to confirm that you have optimized your carton flow rack design for your inventory specs, call the gravity flow experts at Mallard. Our team can test out your system before purchasing the components to make sure it will meet all expectations. We are also able to provide advice and cost-saving measures where applicable.

For more carton flow rack design tips, check out our blogs: