Ergo Build Mixed-SKU Pallet Building with Pallet Flow

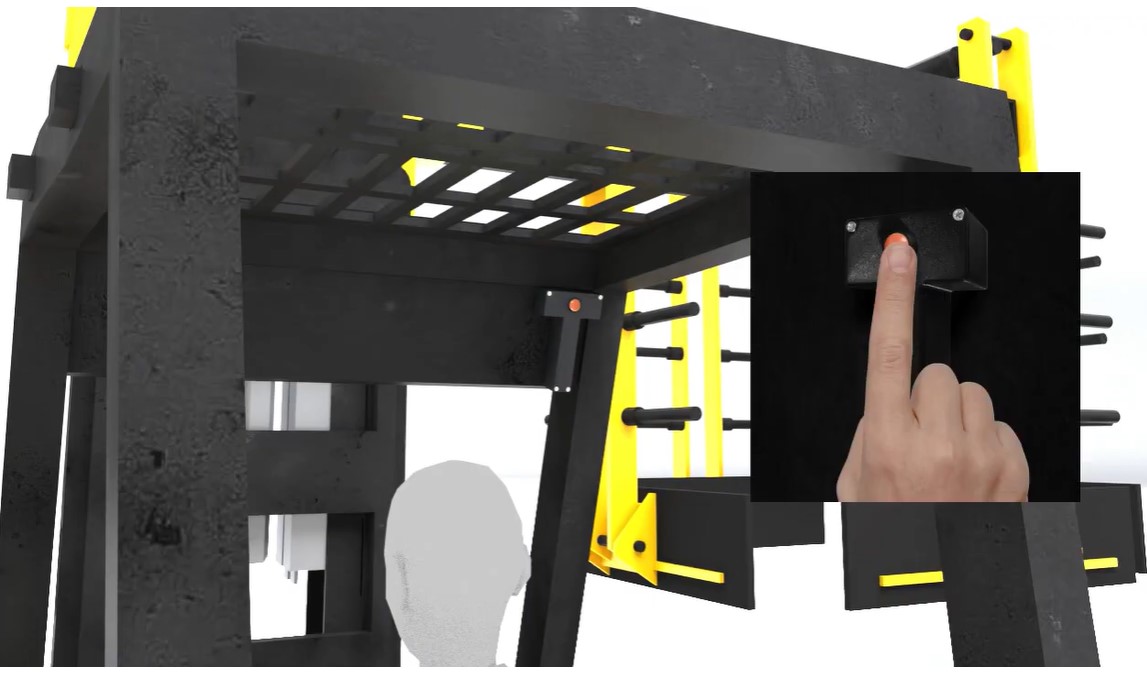

Enhance productivity and safety with the push of a button…

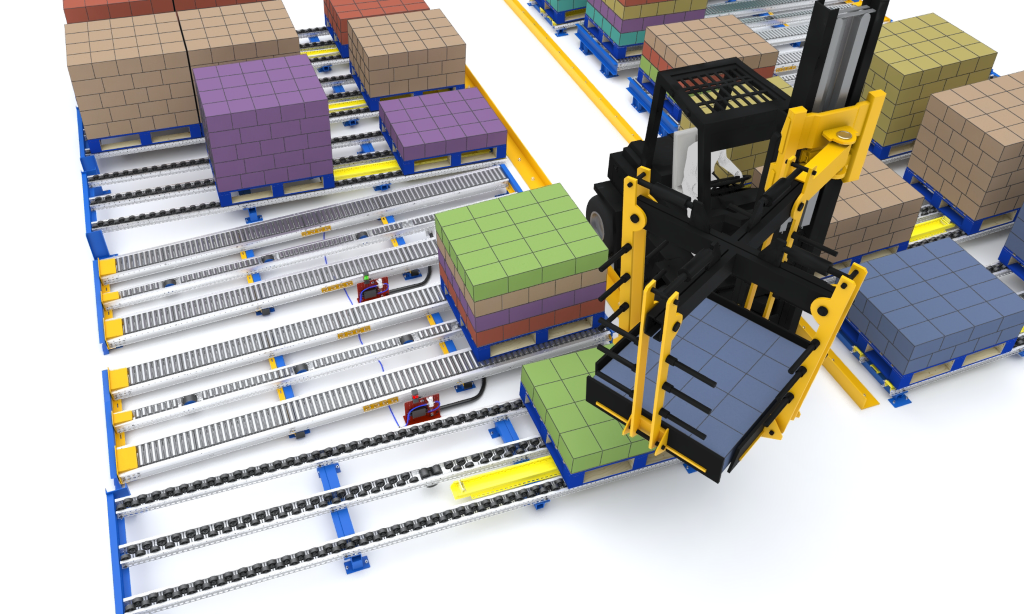

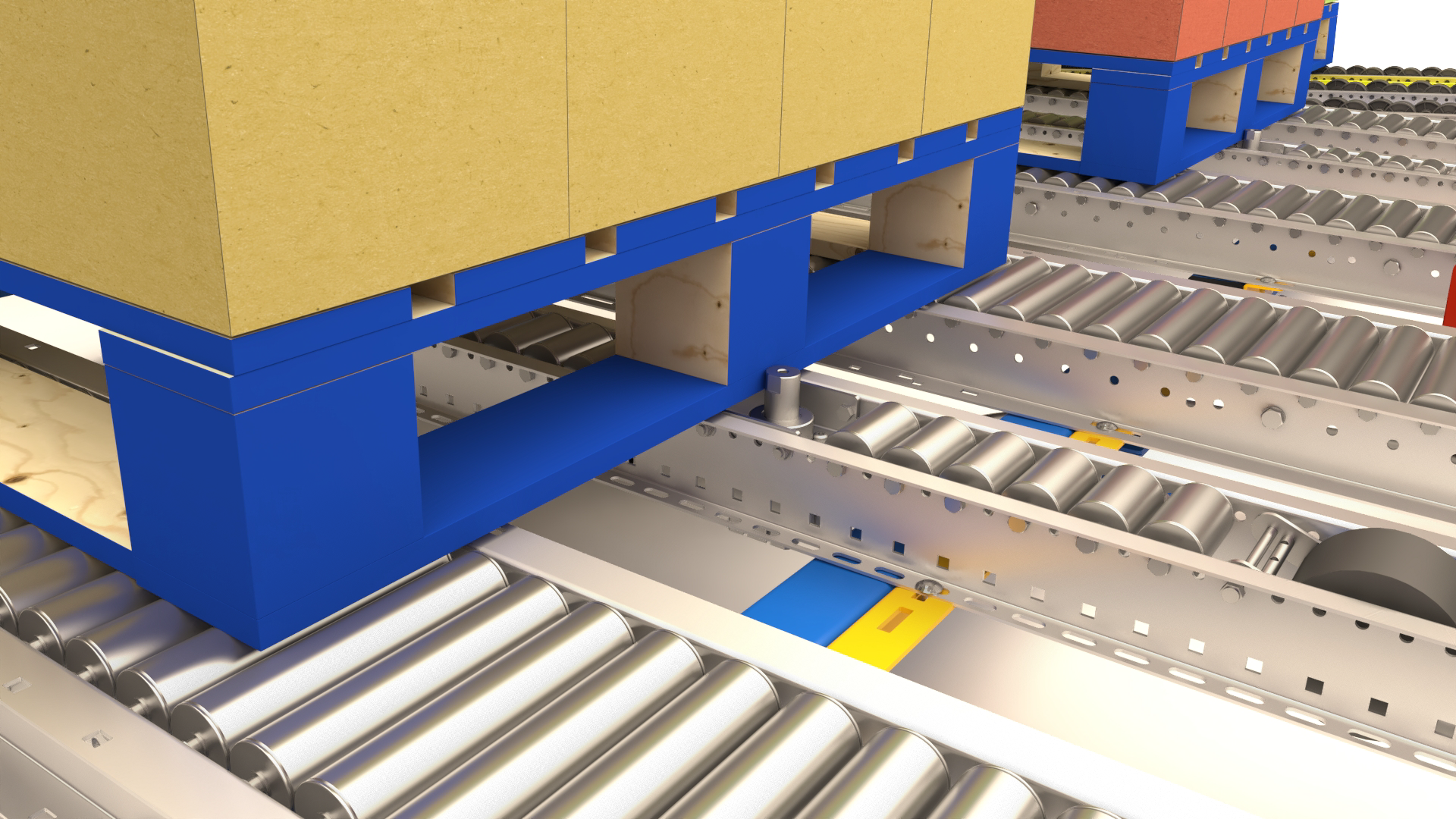

The Ergo Build (patent pending) application pairs outbound and inbound pallet flow lanes to create an optimized workflow for mixed-SKU pallet building.

The Ergo Build-equipped outbound lanes hold pallets at the pick aisle for mixed-SKU pallet building.

The inbound pallet flow lanes keep inventory coming to supply the layer pick operator. This combination of automatically refreshed inbound inventory and mixed-SKU pallet building right within the pick aisle streamlines the activity increasing productivity.

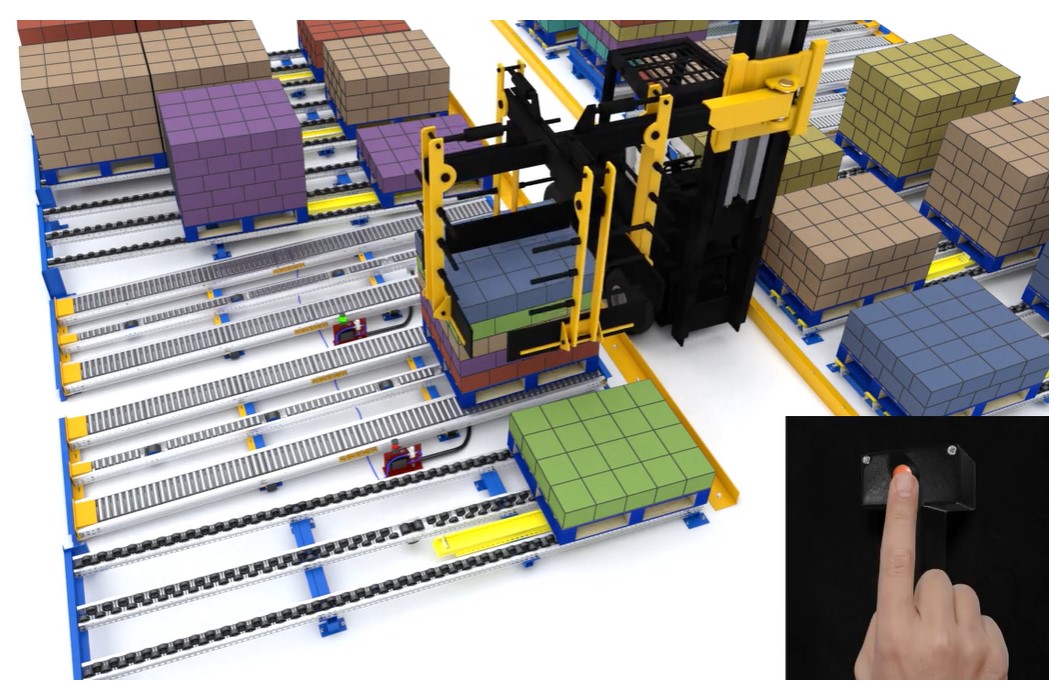

Once the mixed-SKU rainbow pallet is complete, the operator simply presses the release button inside the vehicle. This triggers the Ergo Build pneumatic pop-up in the lane to release the pallet to flow to the opposite aisle. The pallet is now free from the layer pick activity and ready for quick, safe pickup.

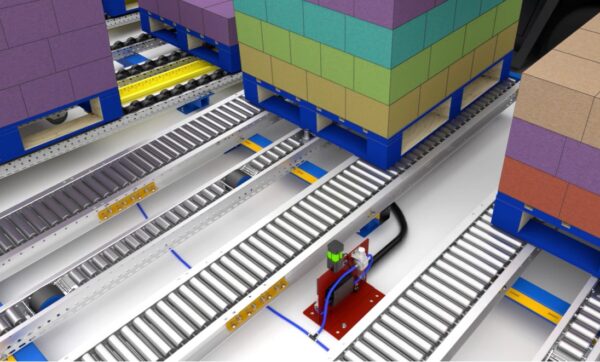

Red and green pedestal lights assure the operator that it is safe to release the pallet and prevent accidental release.

Ergo Build Advantages

- Significantly boost productivity

- Continuous workflow

- Remote-activated pneumatic controls

- No waiting for completed (rainbow) pallet removal

- Built-in safety features

- Safer work area

Ergo Build (EB-800) Design Considerations

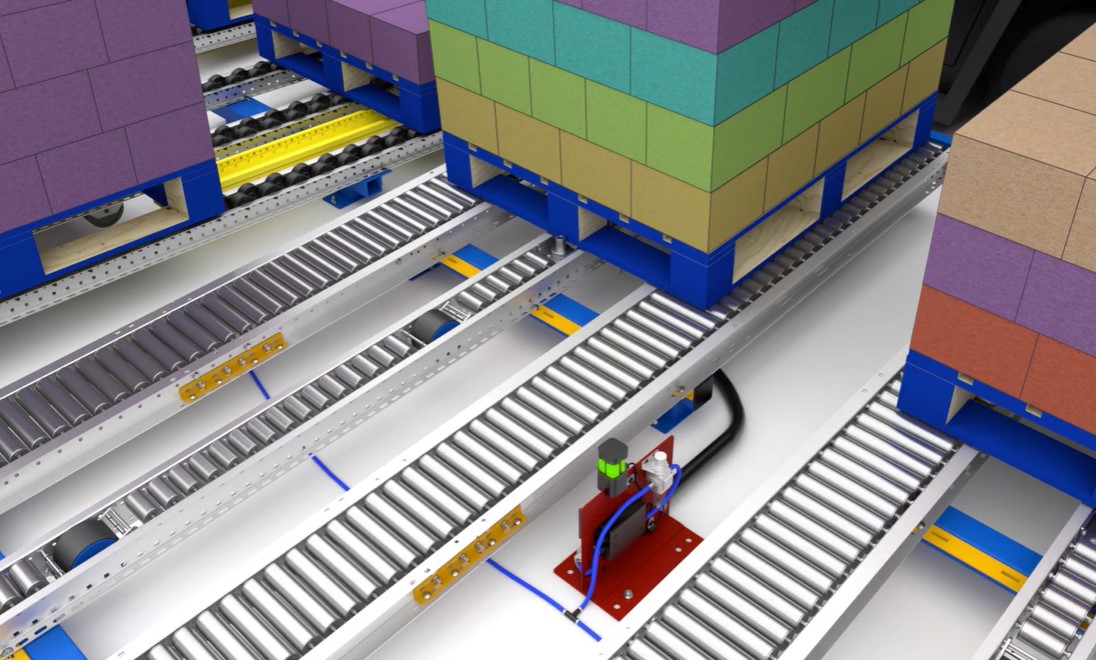

- Position pedestal lights beside the lane

- Pneumatic pop-up separators install in the outbound lanes

- Compatible for layer picking with clamp attachment

- Include clearance for layer pick attachment

- Mallard supports required in the last two positions for proper function

- Maximum 2-5 pallets (3-6 deep) behind the pop-up

Mixed-SKU Pallet Building with Ergo Build & Pallet Flow

Simple as 1, 2, 3 --

- Flank your layer pick aisle with a combination of inbound and outbound pallet flow lanes.

- Inbound lanes flow toward the layer pick aisle and provide a continuous inventory feed for pallet building. They are segmented by SKU and hold reserve stock ready to automatically fill the pick position when needed --no waiting! Layer pick separators isolate the pick aisle pallet, to allow the forklift layer pick attachment to surround and extract the inventory layer(s). The LP-400 separator holds the rear pallets back until the empty pallet is removed from the lane.

- The outbound Ergo Build-equipped flow lanes hold the empty pallet at the pick aisle for mixed-SKU pallet building. Once the pallet is complete, the operator pushes the release button inside the forklift cab, activating the Ergo Build pneumatic separator to release the pallet to flow to the opposite aisle for takeaway.

The Ergo Build enables the forklift operator to continue layer pick and pallet building activities without waiting on inventory, empty pallets, or pallet takeaway.

Green Light - Forklift in Position & Pallet Complete

Button Releases Ergo Build Separator

Separator Drops Down to Flow Pallet

Efficient & Safe -- Next Level Layer Picking with Ergo Build & Pallet Flow

The Mallard team will help you design a pallet flow solution to match your inventory and pallet specs. A properly designed pallet flow system is low-maintenance and durable, providing years of reliable activity.

Visit our galleries for system design ideas and more information… better yet, give us a call to schedule a consultation. Our gravity flow experts are ready to put gravity to work for you and your team.