Global Food Producer isn’t Chicken about Finding Best Pallet Flow Design

SOLUTIONS

FOR THE TOUGHEST APPLICATIONS

"*" indicates required fields

We’ve got a week to go before the most important dinner of the year! Since it’s precise supply chain planning and warehouse controls that ensure a happy Thanksgiving table for millions, the Mallard team has been busy at work providing the most efficient pallet flow configurations to support our food producing customers.

One of those customers was interested in finding an effective solution for unusually wide (66”) and shallow (24”) metal pallets of varying inventory weights. This customer was already using a steel skate wheel pallet flow system for other inventory in one of their warehouse facilities, so we began our testing with that option first. Our test was to confirm the skate wheel system effectiveness across a more varied inventory and to see if there was another pallet flow option that would prove more reliable.

The Mallard team fired up the Engineering Testing Lab and the outcome may surprise you. Here’s the test comparing steel skate wheel and Magnum polycarbonate wheeled pallet flow systems.

Pallet Flow Lane Test Design #1

- 3 rails – 1.9” diameter steel skate wheel pallet flow

- 2” / 3” / 2” centers (final)

- Drop-in speed controllers @ 66” intervals

- Pallets – 66” x 24” metal with three bottom runners

- Pallet weights from 720 – 1200 lbs.

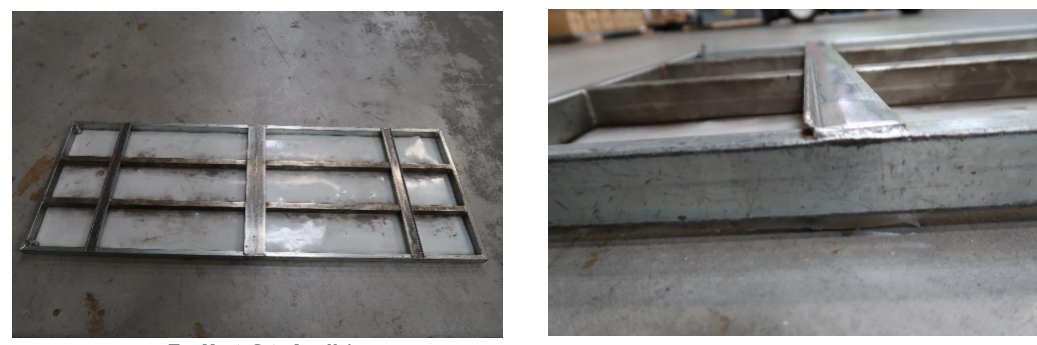

Customer-Supplied Pallets

The skate wheel pallet flow lane design was comprised of three rails, including a center rail, plus drop-in speed controllers spaced on 66” centers to ensure regular contact with the pallet to control the flow and tracking down the lane. The Mallard speed controllers are rubber coated and more effective at providing good contact and controlling the customer-supplied metal pallet vs. the kind that they were currently using in their existing skate wheel system.

In the test, the Mallard engineers staggered the wheels in the center lane on 1-1/2” centers, but due to the thickness of the center runner on the pallets, they noticed that the pallet only came in contact with wheels on one side, effectively rolling on 3”centers. If the skate wheel lane design was ultimately requested by the customer, then the system would be designed with all wheels on 3” centers offset to one side. The test proved well overall with the exception of the lighter loads (720 lbs.) that tended to hang up. The heavier 1000-1200 lbs. loads flowed consistently without hang ups.

Pallet Flow Lane Test Design #2

- 3 rails – 2.9” diameter polycarbonate wheel pallet flow

- 3” / 4” / 3” wheel centers

- Drop-in speed controllers @ 56” intervals

- Pallets – 66” x 24” metal with three bottom runners

- Pallet weights from 720 – 1200 lbs.

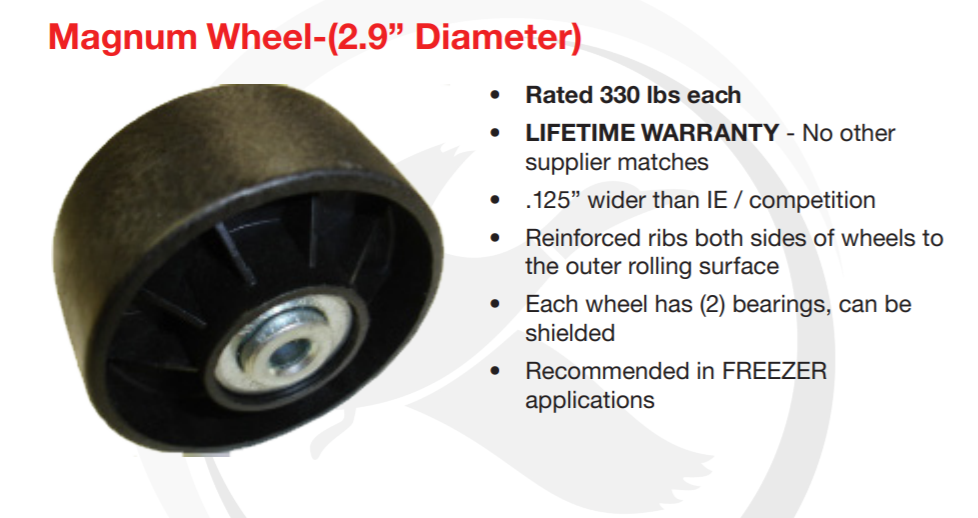

The Magnum wheel pallet flow lane was also configured with 3-rails. The system was set up with the outside rails on 3” centers and the center rails staggered on 2” centers. Coincidentally, as with the skate wheel system, the pallets only connected with one side of the wheels effectively riding on 4” centers.

The polycarbonate pallet flow lane showed very good results with the varied weights from 720-1200 lbs. No hang ups were noticed. The speed controllers were set at 56” in this system to minimize the effect of a slight surge of the pallet between speed controllers. To fully test out the effectiveness of the system for varied loads we also tested it with 500 lb., 300 lb. and 150 lb. loads… all of which showed positive results. The lightest load showed a slight hang up but was easily restarted with a gentle nudge.

The polycarbonate pallet flow lane showed very good results with the varied weights from 720-1200 lbs. No hang ups were noticed. The speed controllers were set at 56” in this system to minimize the effect of a slight surge of the pallet between speed controllers. To fully test out the effectiveness of the system for varied loads we also tested it with 500 lb., 300 lb. and 150 lb. loads… all of which showed positive results. The lightest load showed a slight hang up but was easily restarted with a gentle nudge.

Test Results

While the steel skate wheel lane was highly effective with the heavier loads, it was less consistent with the lighter 750 lb. load. If there is a possibility of lighter loads, then this lane could prove less effective than the Magnum wheeled lane. The polycarbonate wheels tested very consistently across the wide variety of pallet inventory weights. In addition, Magnum wheels are guaranteed with a Lifetime Abuse Warranty.

Final Thoughts

This test is an excellent example of why we test in the first place. The customer is currently using a pallet flow system, therefore it would be easy to just order more of the same, However, because inventory parameters are different for the new facility the wise decision was to check out system effectiveness before placing the order and assuming everything would work the same. Not only did we find a better, more productive, and guaranteed pallet flow option, we were able to identify a superior speed controller to work with the customer’s metal pallets.

Food producers work hard all year to provide us with quality products. We’re thankful to provide them with safer and more-productive tools to do their job. If you have a warehousing challenge you’d like to have the Mallard engineers test out… contact our team today.