Mallard Introduces — New & Improved Pallet Flow Pallet Separators

SOLUTIONS

FOR THE TOUGHEST APPLICATIONS

"*" indicates required fields

Pallet Separators Work to Merge Warehouse Safety with Productivity

Take the pressure off your warehouse storage and picking applications and improve warehouse safety and productivity at the same time with pallet flow separators. Pallet separators are installed in pallet flow lanes to isolate the front pick face pallet from the rear pallets thereby removing back pressure inherent in a gravity flow application. All the benefits of gravity flow remain… reserve storage, automatically replenished pick face, congestion-free loading, and picking, etc. but the operation is enhanced with the use of pallet separators. When the front pallet is free from pressure it is faster, easier, and safer to remove whether it’s by a forklift at 30’ up in the air or a worker in a case pick area. Faster, easier, and safer equals cost-effective, productive warehouse activity.

Watch Mallard’s Case-Pick Separator in action…

Show Me the Numbers

What are we really talking about when we say safer warehouse operation? Here is how we calculate back pressure and two examples to show the extent of pressure that pallet separators remove from the pallet flow lane:

Back Pressure = .06 x (maximum pallet load weight) x # of pallets. E.g. 3-deep system, 2,500 lb. load. Back pressure = .06 x 2,500 lbs. x 2 pallets = 300 lbs. 20-deep system, 2,500 lb. load. Back pressure = .06 x 2,500 lbs. x 19 pallets = 2,850 lbs.

Hundreds to thousands of pounds are removed depending on the lane depth… and again, all the benefits and features of pallet flow remain.

What’s New & What’s Improved

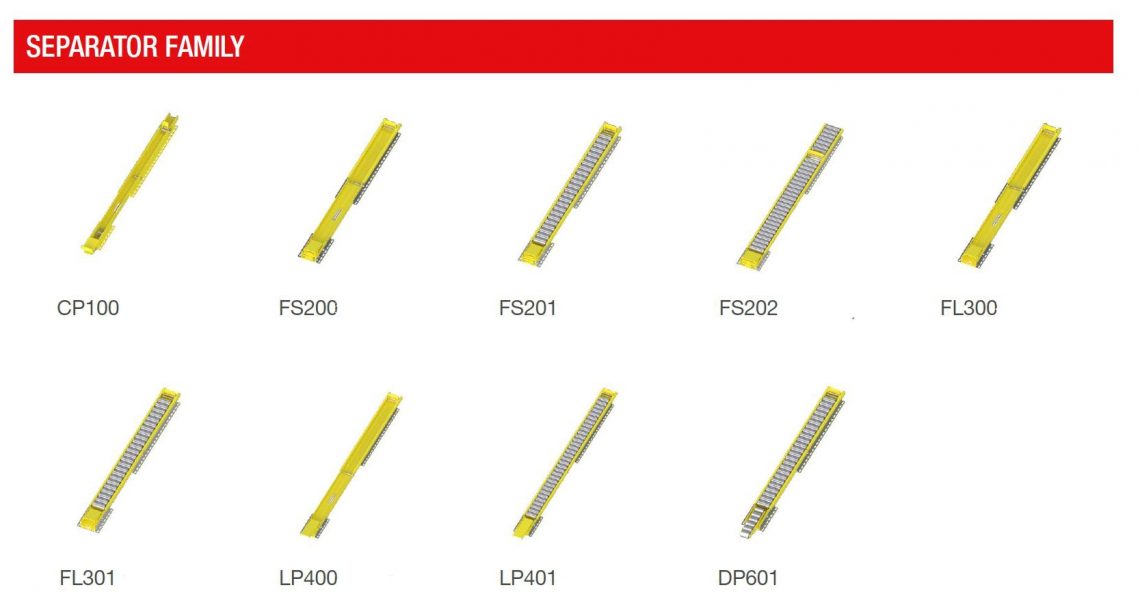

The pallet separator line of products has been updated to meet the warehouse challenges of today and help our customers position themselves for tomorrow. The products offered in the pallet separator line are:

Case pick separator – updated and enhanced for use with all Mallard pallet flow products and with the capacity of up to 10,000 lbs. and up to 3 pallets behind the separator (4 deep lane). See our website for system specs and operational video.

|

CP 100 |

|

Flex Separator – now offering 3 products to serve all your deep-lane (4-8 pallets deep) case picking needs. See our website for system specs and operational video.

- FS 200 for standard GMA-style pallets

- FS 201 for non-GMA style & plastic pallets

- FS 202 for heavy-duty applications

- FRFS 202 for 1.9″ full roller applications

|

FS 200 |

FS 201 |

Forklift Separator – designed to enhance the safety of forklift pallet removal from deep-lane, multi-level pallet flow no matter what type of pallet. See our website for system specs and operational video.

- FL 300 for standard GMA-style pallets

- FL 301 for non-GMA style & plastic pallets

|

FL 300 |

FL 301 |

Layer-Pick Separator – mixed pallet custom order fulfillment for inventory on standard and non- standard pallets with our newly designed LP Series separators. See our website for system specs and operational video.

- LP 400 for standard GMA-style pallets

- LP 401 for non-GMA style & plastic pallets

|

LP 400 |

LP 401 |

Ergo Cell Pneumatic Separator & Lift Table – ergonomic solution to high-volume case-picking of heavy cases or cartons picked from pallets. Pneumatic button operates the separators to release the pallet onto the lift table and a foot pedal raises the hydraulic lift table to a comfortable pick height. See our website for system specs and operational video.

|

PS 500 |

|

Dual-Pallet Separator – deep-lane and extra-deep pallet flow lanes require a set of pallet separators designed to work in tandem to ensure the safety of your team and operations. The DP Series is designed to work with all Mallard pallet flow products and pallet types up to 30,000 lbs. in the lane. See our website for system specs and operational video.

- DP 600 for standard GMA-style pallets

- DP 601 for non-GMA style & plastic pallets

|

DP 600 |

DP 601 |

Empty Pallet Return Lane – there’s one EPR 700 to meet all your empty pallet return needs but there are four types of lane configurations to ensure your system is best fitted to your case pick operation for optimized productivity. See our website for system specs and operational video.

- Single Empty Pallet Return

- Stacked Empty Pallet Return

- Vertical Pallet Return

- Double-Sided Vertical Pallet Return

|

EPR 700 Vertical Pallet Return |

EPR 700 – Stacked Pallet Return |

See Our Complete Line of Pallet Separators

We have updated our pallet separator brochure that is available for free download from the Mallard website. Please feel free to access the brochure and if you need additional help designing your pallet flow system or configuring the right pallet separator with your system, call the Mallard gravity flow experts. Our team is ready and available to help you find the solution that will work best for your operation.